SAME DAY DELIVERY

SAME DAY DELIVERY

SAME DAY DELIVERY

SAME DAY DELIVERY

SAME DAY DELIVERY

SAME DAY DELIVERY

SAME DAY DELIVERY

SAME DAY DELIVERY

SAME DAY DELIVERY

SAME DAY DELIVERY

SAME DAY DELIVERY

SAME DAY DELIVERY

SAME DAY DELIVERY

SAME DAY DELIVERY

SAME DAY DELIVERY

SAME DAY DELIVERY

SAME DAY DELIVERY

SAME DAY DELIVERY

SAME DAY DELIVERY

SAME DAY DELIVERY

MAPEI Keraflor Thin-Set Tile Mortar 50 lb. - White

-

Vendor:

Mapei

Pickup available at Go Build, Brooklyn Location

Usually ready in 2 hours

Description

Description

Keraflor is a dry-set mortar for use in interior/exterior residential and light commercial floor applications.

FEATURES AND BENEFITS

▪ For interior/exterior floors

▪ Can be used over plywood substrates when mixed with Keraply

INDUSTRY STANDARDS AND APPROVALS

▪ ISO 13007: Classification C1 when mixed with water; classification C2S1 when mixed with Keraply

▪ ANSI: Exceeds ANSI A118.1 bond strength requirements when mixed with water; exceeds ANSI A118.4 and ANSI A118.11 bond strength requirements when mixed with Keraply

WHERE TO USE

When mixed with water:

▪ Most interior/exterior residential installations on floors

▪ Installation of ceramic tile, quarry tile, pavers and Saltillo tile

When mixed with Keraply:

▪ Most interior/exterior residential and light commercial oor installations

▪ Installation of ceramic and porcelain tile, quarry tile, pavers, Saltillo tile, and most types of marble, granite and natural stone

LIMITATIONS

▪ Install only at temperatures between 40°F and 95°F (4°C and 35°C).

▪ Do not use for moisture-sensitive stone (green marble; some limestone and granite), agglomerate tiles, or resin-backed tiles. Instead, use suitable epoxy or urethane adhesives.

▪ Do not use over dimensionally unstable substrates such as hardwood flooring, oriented strand board (OSB), substrates containing asbestos, or metal.

▪ For light-colored and translucent natural stone, a white mortar is recommended.

▪ Do not use for installations subject to water immersion, such as pools and spas.

▪ Not recommended for areas subject to severe freeze/thaw conditions. For the best performance, use a MAPEI mortar system with a liquid latex additive.

SUITABLE SUBSTRATES

When mixed with water:

▪ Concrete (cured for at least 28 days)

▪ Cement mortar beds and leveling coats

When mixed with Keraply"

▪ The substrates listed above

▪ Cement backer units (CBUs) – see manufacturer’s installation guidelines

▪ Plywood underlayments must be a Group 1 exterior-grade plywood CC-plugged or better, conforming to APA classification and U.S. Product Standard PS 1-95 or a “SELECT” or (SEL-TF) CANPLY classified exterior-grade plywood conforming to CSA-0121 standard for Douglas r for direct-bond applications (interior, residential

and light commercial oors and countertops in dry conditions only).

SURFACE PREPARATION

▪ All substrates should be structurally sound, stable, dry, clean, and free of any substance or condition that may reduce or prevent proper adhesion.

MIXING

Before product use, take appropriate safety precautions. Refer to the Safety Data Sheet for details.

1. Into a clean mixing container, pour about 5 to 6 U.S. qts. (4.73 to 5.68 L) of clean potable water, or 1.5 to 2 U.S. gals. (5.68 to 7.57 L) of Keraply.

2. Gradually add 50 lbs. (22.7 kg) of powder while slowly mixing.

3. Use a low-speed mixing drill (at about 300 rpm), with an angled cross-blade mixer or spiral mixer. Mix thoroughly until the mixture becomes a smooth, homogenous, lump-free paste. Avoid prolonged mixing.

4. Let the mixture stand (“slake”) for 5 minutes.

5. Remix for 1 minute.

6. If the mixture becomes heavy or stiff, remix it without adding more liquid.

PRODUCT APPLICATION

Read all installation instructions thoroughly before installation.

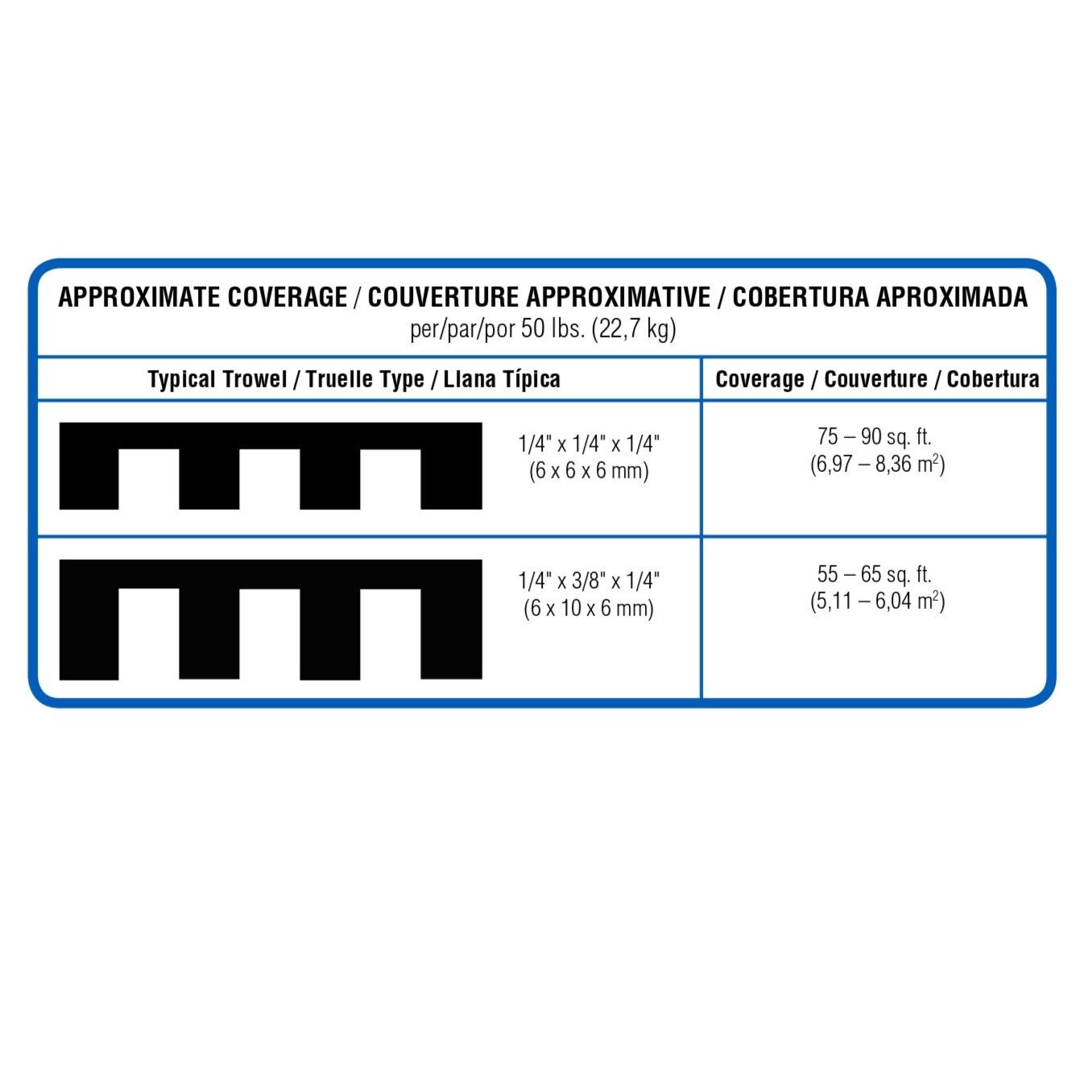

1. Choose a notched trowel (see the “Approximate Coverage” chart below) with sufficient depth to achieve more than 80% mortar contact to both the tile and substrate for all interior applications, and more than 95% for exterior installations and wet applications. It may be necessary to back-butter the tile/stone in order to

meet these requirements. (Refer to ANSI A108.5 specifications and TCNA Handbook guidelines.)

2. With pressure, apply a coat by using the trowel’s at side to key mortar into the substrate.

3. Apply additional mortar, combing it in a single direction with the trowel’s notched side.

4. Spread only as much mortar as can be tiled before the product skins over. Open time can vary with jobsite conditions.

5. Place the tiles rmly into the wet mortar. Push the tiles back and forth in a direction perpendicular to trowel lines, to collapse the mortar ridges and help achieve maximum coverage. Ensure proper contact between the mortar, tile and substrate by periodically lifting a few tiles to check for acceptable coverage.

6. Remove excess mortar from the joint areas so that at least 2/3 of the tile depth is available for grouting

CLEANUP

▪ Use water only to clean tools and tile while the mortar is fresh.

PROTECTION

▪ Protect from traffic for 24 hours. Protect from heavy trafifc for 7 days.

▪ Protect from frost and rain for 7 days.

Specifications

Specifications

-

Fast Local Delivery

Fast Local Delivery with same day delivery of thousands of products.

-

Professional Customer Support

Professional live support ready to help with any question or inquire with more then 30 years experience in construction industry.

-

Competitive / Negotiable Prices

Competitive prices together with excellent service, with unique live negotiate AI tool.

-

Top Brands

Top brands in stock ready to ship at anytime with more then 5,000 products to complete your project.

NATIONWIDE SHIPPING

NATIONWIDE SHIPPING

NATIONWIDE SHIPPING

NATIONWIDE SHIPPING

NATIONWIDE SHIPPING

NATIONWIDE SHIPPING

NATIONWIDE SHIPPING

NATIONWIDE SHIPPING

NATIONWIDE SHIPPING

NATIONWIDE SHIPPING

NATIONWIDE SHIPPING

NATIONWIDE SHIPPING

NATIONWIDE SHIPPING

NATIONWIDE SHIPPING

NATIONWIDE SHIPPING

NATIONWIDE SHIPPING

NATIONWIDE SHIPPING

NATIONWIDE SHIPPING

NATIONWIDE SHIPPING

NATIONWIDE SHIPPING